injection molding machine and injection side

injection molding machines

Most injection molding machines use a single electric motor to drive the hydraulic system for the entire machine. One inherent advantage of the molding cycle is that the power requirement for the hydraulic system is smoothed out because the various phases occur in sequence,As a result, a 200-ton (182-tonne) machine uses only one 40-HP (30-kw) motor; a 500-ton machine about 75 HP, and a 1000-ton machine only about 150 HP. (An additional 70-100 or more kilowatts of heater capacity must be accomodated for the 1000 ton machine.) Hydraulic system design for energy conservation is the subject of much current attention by machine builders and overall energy costs should be considered carefully by the molder.

Most hydraulic systems use fixed displacement pumps, and electrohydraulic servovalves for flow control to obtain stepless speed variation of hydraulic motors and cylinders. Hydraulic motors are efficient providers of high torque at low speeds and can be directly connected to the extrusion screw without extra mechanical transmission components. In medium and large machines, hydraulic accumulators are used to provide higher injection capacity. Redesign of circuits using cartridge valves connected {hrough manifolds instead of freestanding valves connected by pipe or hose has been hampered by high costs. These fast, compact circuits have been compared to digital electronic circuits, and the term digital or integrated hydraulics is used to describe them.

Desktop Injection Molding Machine

Injection Side

As in extrusion, general practice for screw selection with a resin that is new to a particular molder is to obtain a recommendation from the resin supplier. If a new screw has to be ordered, then rheological data on the resin should be provided so that the screw manufacturer can apply a computer program for optimum screw design. The L/D ratios for injection molding range from 16:1 to 30:1, and is most commonly about 20:1. Compression ratios range from 2:1 to 3:1. Screw and barrel designs are very similar to those described in Chapter 8 for extruders, but there is less concern with melt stability and maximum throughput than there is in profile or sheet extrusion applications. For this reason, so-called general purpose screws are often used. The length of these screws is divided as follows: about 60% for the feed section, 2 0% for transition, and 2 0% for metering. The feed depth is typically 0.20 D and the metering depth about 0.08 D, where D is the screw outside diameter.

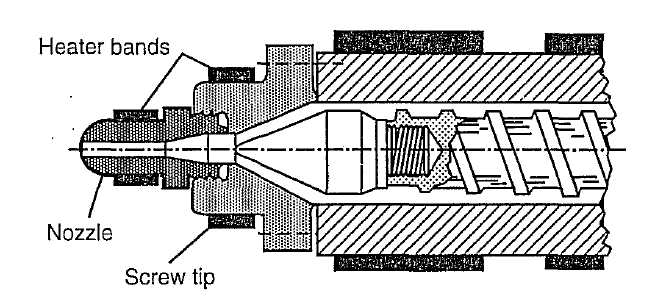

The action of the screw as a plunger during plastic injection could permit melt to leak back into the barrel and decrease efficiency. However, for relatively viscous and beat-sensitive materials, such as PVC, a plain tapered, screw-in tip is adequate (Fig. 9.8). Rapid forward motion of the screw does not permit excessive back flow. For less viscous plastics, nonreturn valves are often recommended. The free flow, sliding ring type is popular (Fig. 9.7). In sliding-ring, nonreturn valves, when the screw is rotating, plastic melt pressure forces the ring forward so that melt can flow freely. During injection, the ring slides back and seals against a lapped seat on the valve body. The small amount of material trapped in front of the ring during injection must be flushed out during the next plasticizing phase. 9.3 Machine Construction Details 281 Figure 9.8 A plain, screw-in tip for heat-sensitive plastics. This is also called a smear tip to describe its self-cleaning function. A short, open-bore nozzle for medium to high-viscosity melts (provided with a separate heating band) is shown screwed into the end of the barrel. The free flow area of the valve should be at least 80% of the flow area in the metering section of the screw.

Ball check valves are favored by some molders for ease of maintenance and low cost. Care should be taken that the valve does not introduce excessive shear heating and material degradation. A measure of the effectiveness of a nonreturn valve is the statistical distribution of part weights. If there is a wide distribution, it may indicate a leaking valve. A good distribution should have a standard deviation in part weight of the order of 0 .1%.

The nozzle is an adapter, fastened to the barrel, that provides a mechanical and thermal connection between the hot barrel and the much cooler mold. Since melt flows through the nozzle at a very high velocity during injection, the nozzle should offer minimum pressure loss consistent with prevention of excess drool prior to the injection phase. It is always preferable to use a plain open-bore nozzle rather than a more complex shutoff valve type. A short open-bore nozzle with a minimum orifice of 5 mm is a common design . A heater band and thermocouple are provided. The spherical seat on the nozzle, about 15 mm in radius, is designed to seal against the sprue bushing. The sprue bushing opening is slightly liarger than the nozzle orifice to ensure that the sprue can be pulled even if the nozzle and sprue are slightly misaligned.

Figure 1 shows a positioning or pull-in cylinder on the injection carriage. The carriage is pulled back during purging and to obtain access to clean the extruder and replace the nozzle and screw tip. It is also used to provide a sprue break feature, as previously explained. The stationary half of the mold, attached to the die head (stationary platen), is clamped against the nozzle by this cylinder.